What is DAC®

DAC® – Description

DAC® is a Class III, EC marked medical device.

DAC® is composed of two bioresorbable polymers: Hyaluronic acid and Poly-lactic acid

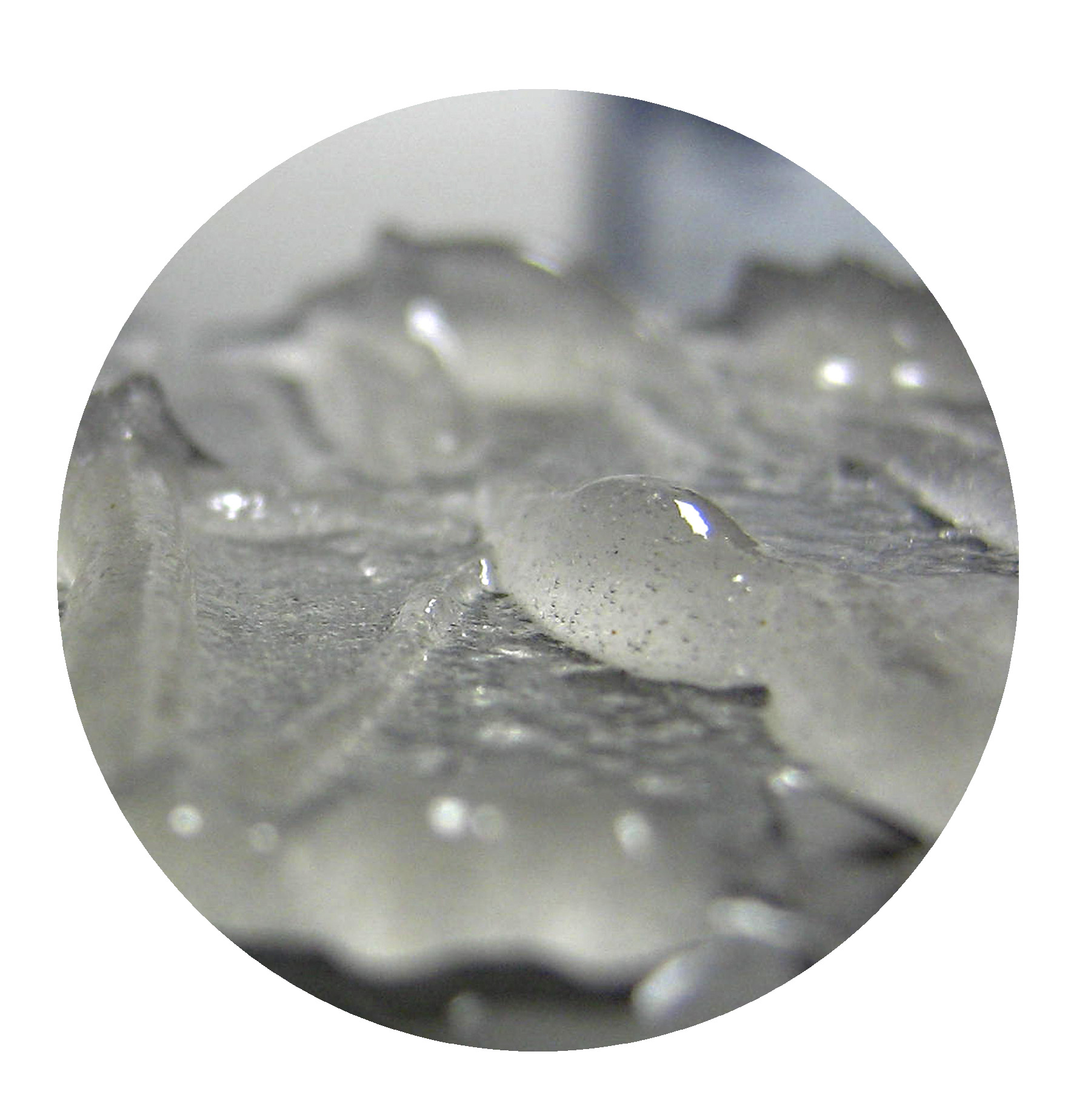

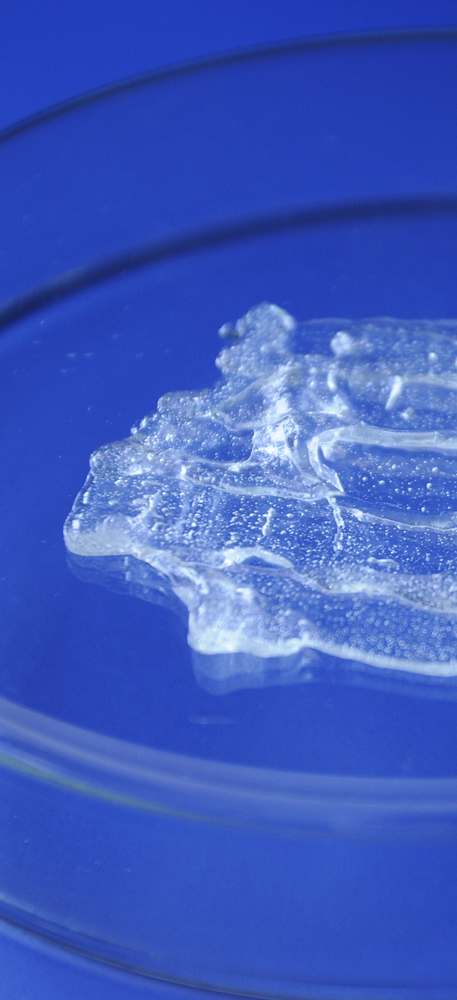

It is produced in the form of a powder that, to obtain the hydrogel formulation, must be hydrated with water for preparations that are injectable alone, or in solution with an antibiotic. The indication is the prevention of peri-implant infection.

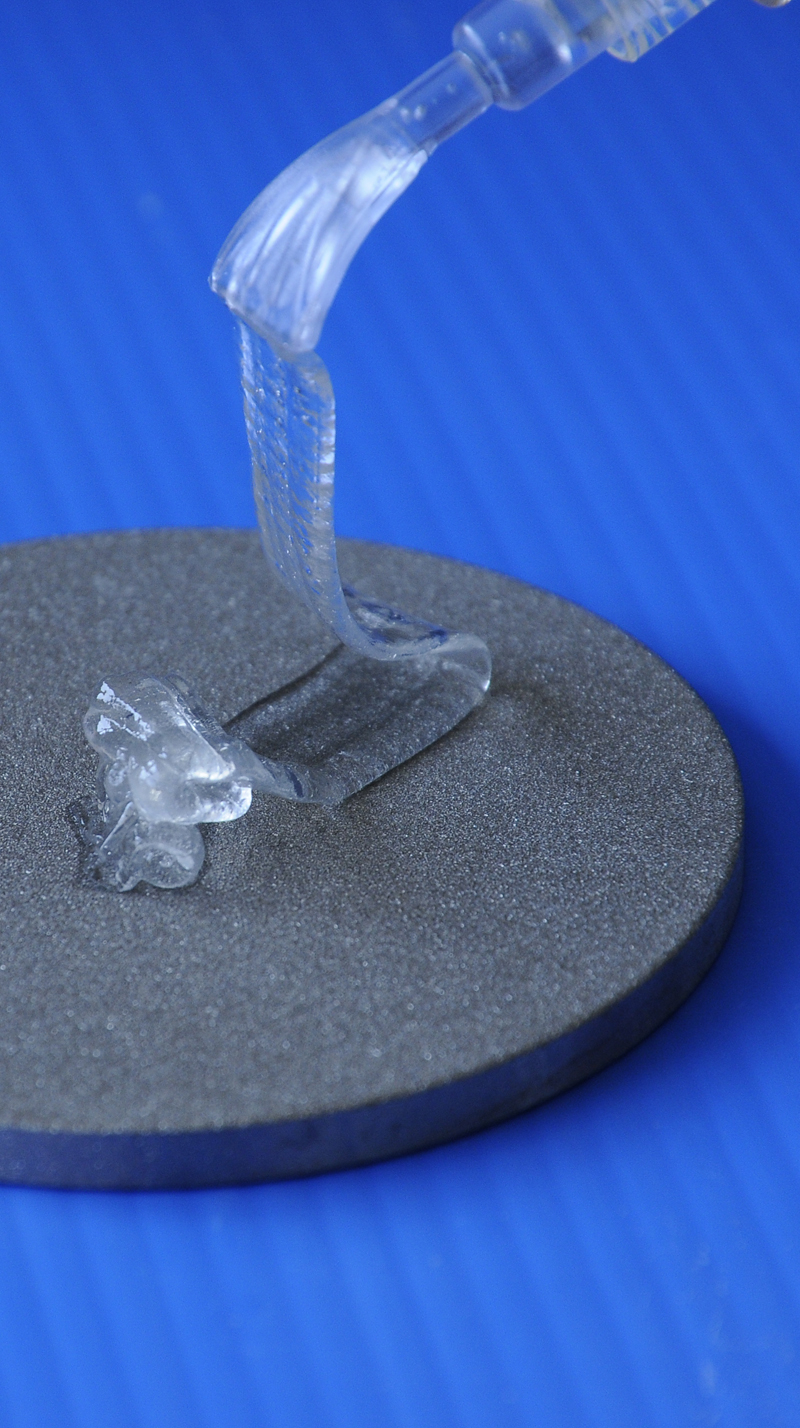

Said prevention is obtained by coating the implant components or internal fixation devices with DAC® hydrogel before implant insertion in the operating theatre in order to create a protective barrier against bacterial adherence.

REFERENCES:

- Luo Y, Kirker K, Prestwich G. Modification of natural polymers: hyaluronic acid. Methods of tissue engineering. Orlando Academic Press 2001:539-553

- Morra M, Cassinelli C. Wettability and surface structure of hyaluronic acid and hyaluronic acid ester foulingresistant coatings. In ACS polymeric materials science and engineering. San Francisco: ACS 1997:566-567

- Francolini I, Donelli G. Prevention and control of biofilm-based medical device-related infections. FEMS Immunology & Medical Microbiology 2010;59:227-238

- Cassinelli C, Morra M, Pavesio A. et al. Evaluation of interfacial properties of hyaluronan coated poly(methylmethacrylate) intraocular lenses: J Biomaterials Science 2000;1:961-977

- Pavesio A, Renier D, Cassinelli C. et al. Anti-adhesive surfaces through hyaluronan coatings. Medical Device Technology 1997;8:20-24

- Hoekstra D. Hyaluronan-modified surfaces for medical devices. Med Devices Diagn Ind. 1999;February:48-58 Williams D. The biocompatibility, biological safety and clinical applications of Purasorb Resorbable Polymers. S.l. Purac Biomaterials 2010